When Buildings Don’t Behave

There’s a longstanding assumption in engineering that well-designed systems, once deployed, will behave predictably. If the HVAC equipment is efficient, the BMS programmed correctly, and the lighting logic smartly automated, then performance will follow. We are trained to trust this process — to model, simulate, optimize, and refine until the outcome aligns with the specification. But in the real world, this logic frequently fails.

Despite good systems, performance gaps persist. We encounter buildings where energy savings plateau, comfort complaints remain unresolved, and systems quietly drift out of alignment over time. The spreadsheets say one thing; the field says another. And when we investigate, we often discover the issue isn’t technical at all. It’s human.

“The System Isn’t the Only Variable“

What undermines efficiency isn’t necessarily the system, but how that system is used — or ignored. It’s in the open window beside the radiator. The portable heater under the desk. The manual override that no one logged. The meeting room that stays lit because no one feels responsible for turning off the lights. These moments don’t register on the design model, but they accumulate. Over months and years, they shape the building’s energy profile far more than most engineers care to admit.

At BAARCH, we’ve spent the better part of a decade walking this line between technical clarity and operational complexity. We’ve worked across sectors — in offices, schools, cultural spaces, and manufacturing facilities — and we’ve seen the same reality repeat itself: performance is as much about behavior, context, and perception as it is about systems and controls.

Eventually, we had to ask a harder question: what if buildings don’t just need better systems? What if they need a different relationship between the people who use them and the energy they consume?

This line of inquiry led us to a project that fundamentally shifted our view of what engineering can — and should — do.

I. A Turning Point: Observing People, Not Equipment

In 2018, we joined a multi-partner research-action project in France called PAPEO — short for Pratiques d’Actions Pro-Écologiques au travail (Pro-Environmental Practices at Work). The initiative was funded by ADEME, and co-led by psychosociologists, building engineers, and local institutions, including the Conseil Départemental du Pas-de-Calais. Its purpose was to explore whether energy-related behaviors in the workplace could be transformed — not through technology or mandates, but through peer influence and organizational dynamics.

The test environment was a large administrative complex of over 900 employees spread across eight buildings. The baseline energy systems were modern but unremarkable — no smart automation, no AI, no recent retrofits. In other words, a perfect site to study how culture, rather than hardware, might drive change.

We were not studying preferences. We were testing practice.

The methodology was rigorous but simple. Could real energy behavior be shifted through peer influence, feedback loops, and cultural ownership — even when technical systems remained untouched?

This was not a theoretical inquiry. It was a long-term, real-world intervention in a live public institution. And it offered us the chance to witness, with unusual clarity, what most engineers overlook: how and why people choose to engage with energy, or disengage from it entirely.

II. What We Learned

Over the course of nearly a year, the PAPEO project gave us sustained visibility into how energy use emerges from people, not just from systems. This wasn’t a study about attitudes, nor an awareness campaign. It was a deep, structured experiment in human behavior under operational conditions. What we learned in that process has shaped how we approach engineering ever since.

1. Technology Can Enable Change — But It Doesn’t Create It

At the start, all three groups operated under similar technical conditions. Each had working thermostats, metering systems, and standard heating/cooling infrastructure. The difference wasn’t in the equipment — it was in how people interacted with it.

The “control” group, left to its own routines, showed virtually no change. Meanwhile, the horizontal group — with no technical intervention, but with peer-led engagement — achieved measurable reductions in energy use. The lighting load dropped by an estimated 20 kW, equivalent to over 550 fluorescent lamps removed or switched off. Heating demand decreased by 5–11%, based solely on behavioral shifts .

None of this required a system upgrade. What changed was not the system, but the relationship people had to it.

This lesson is critical: technology facilitates change, but only culture sustains it. Without social traction, even the smartest control loop can be bypassed, ignored, or fought against.

The project deliberately avoided traditional retrofit approaches. Instead of replacing equipment, it relied on sensors, dialogue, and social design. Eighty temperature probes were installed to map indoor climate dynamics. Baseline questionnaires captured employee perspectives. And most importantly, the site was split into three distinct groups: a control group with no intervention, a “vertical strategy” group using top-down communication, and a “horizontal strategy” group that activated peer-based engagement.

2. Peer Influence Works Better Than Top-Down Instruction

A core part of the experiment tested two distinct engagement strategies: a classic “vertical” approach based on expert instruction, and a “horizontal” approach grounded in peer leadership.

In the vertical group, energy-saving messages were broadcast from the top: through email, posters, and formal communication. The results were underwhelming. By contrast, the horizontal group was supported by a small team of volunteer employees trained as Econautes — peer leaders with no formal authority, whose role was to listen, encourage, and lead by example.

They didn’t give orders. They built trust.

The presence of Econautes shifted the dynamic from compliance to curiosity. Colleagues began talking about energy without prompts. Shared commitments became visible. Small shifts — switching off lights, adjusting temperature settings, unplugging idle devices — began to take root as norms.

These changes didn’t stem from top-down logic. They came from peer-to-peer dialogue — the kind that engineers rarely account for, but which turns out to be operationally decisive.

3. Sequence Matters: Start with Action, Then Provide Meaning

The most surprising insight may have been this: it’s not just what you say, but when you say it.

In the vertical approach, employees were first given a description of the energy problem, then invited to change. In the horizontal approach, they were asked first what they were already doing — and only afterward shown how that linked to the broader energy context.

The difference seems subtle, but the impact was clear.

When people were invited to act first — to identify small steps they could take, or already were taking — they responded with a sense of ownership. When the technical explanation came later, it felt like support, not correction.

Inverting the order shifted the emotional frame. The conversation began with the person, not the problem. And in doing so, it activated their agency, rather than their defensiveness.

4. Visibility Sustains Momentum

Behavior change, especially in the workplace, requires more than a one-time message. It needs rhythm. What sustained the horizontal group wasn’t just motivation — it was visibility.

We used three simple tools:

- Regular feedback on building energy performance

- Publicly shared commitment cards

- Visual cues showing who had joined the effort

These created subtle social pressure, but also a shared sense of purpose. People began reminding each other to turn things off. Team leaders asked to join. Conversations that had nothing to do with kilowatt-hours began to circulate organically — and those turned out to be the most effective drivers of all.

In a context where climate communication is often abstract, this made it local, tangible, and actionable.

5. Barriers to Change Are Often Emotional, Not Technical

Throughout the project, we conducted in-depth interviews with dozens of employees — not to measure compliance, but to understand resistance.

What we found was not ignorance. It was emotional blockage:

- “I already do more than others, but no one sees it.”

- “They ask us to turn off the heat, but the windows don’t close properly.”

- “We hear about sustainability, but nothing changes in our space.”

These aren’t objections to the idea of saving energy. They’re expressions of frustration, fatigue, and inequality.

In short: people don’t resist energy goals. They resist feeling unseen, unheard, or unfairly burdened.

This is where many engineering efforts collapse. When efficiency becomes a top-down directive without relational care, it creates disconnection. Technical optimization becomes a source of quiet resentment.

By contrast, when people are treated as full participants — when their constraints and contributions are acknowledged — they become part of the system. And the system starts to work better.

III. What Changed in Our Practice

The PAPEO project didn’t just leave us with findings. It left us with questions. Some of them were simple. Why do we begin our diagnostics at the system layer, when the behavioral layer is often where drift begins? Why do we trust dashboards more than people, when it’s people who ultimately determine how systems are used?

Others were more uncomfortable. Why had we — as engineers — been trained to model systems so precisely, but never to observe how people move through them, adapt to them, or bypass them?

At BAARCH, this led to a quiet but significant evolution in our approach.

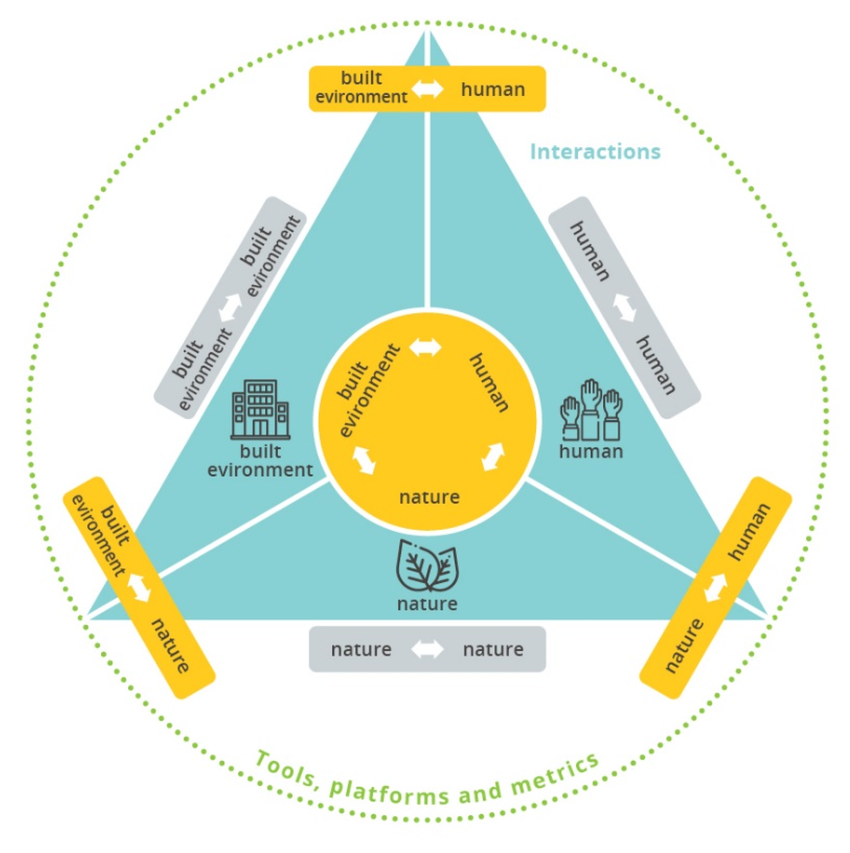

We didn’t abandon our technical expertise. Our work still involves plant rooms, system audits, time-series data, and control logic. But now, we treat those as one part of a broader operational reality. A building is not just a mechanical environment. It’s a social one.

Our audit methodology has evolved accordingly.

We now begin every project with a simple assumption: what’s happening in the building may have less to do with the system, and more to do with the people using it. That assumption isn’t judgmental — it’s investigative. It reminds us to listen before analyzing. To walk the space, talk to the teams, and understand the routines before drawing conclusions from the data.

This shift has also changed how we present recommendations.

Rather than isolating “technical” vs. “behavioral” measures, we’ve learned to frame energy strategy as a conversation — one that requires alignment across management, operations, maintenance, and users. We now map not just systems and faults, but decision patterns. We ask how change is communicated, who carries it, and how it’s maintained.

In some cases, this means we recommend fewer upgrades and more coordination. In others, it means supporting simple behavior-based interventions before any major retrofit is considered. But in every case, it means refusing the idea that energy performance is ever purely a technical outcome.

The value we bring lies not only in identifying savings, but in creating the conditions for those savings to become durable.

That begins, we’ve learned, not with sensors — but with trust.

IV. Impacts and Data

The PAPEO project was not a campaign or a communication experiment. It was designed from the start to produce measurable results — not just in perception, but in actual energy use. The outcomes confirmed what the human insights had already suggested: even without changing the systems, energy behavior can shift. And when it does, the building performs differently.

The experiment ran over several months, tracking both objective and subjective indicators. Eighty sensors provided temperature readings throughout the buildings. Energy data was monitored across heating, cooling, and lighting zones. Surveys and interviews captured the shifting attitudes and emotional landscape of the staff. What emerged was not anecdotal. It was quantifiable.

In several office wings, the average indoor temperature during winter dropped by 2.4°C — without altering the heating setpoint. This reflected a change in how occupants interacted with windows, radiators, and comfort expectations. That reduction translated into an estimated 5% to 11% decrease in heating demand, depending on the baseline conditions.

During the summer period, the cooling load also fell, despite higher outdoor temperatures. This result was not driven by system optimization, but by more consistent use of blinds, rethinking airflow patterns, and greater awareness of unnecessary cooling.

Perhaps the most visible shift came in lighting. The cumulative reduction in lighting load across test zones was estimated at 20 kW, roughly equivalent to deactivating or removing over 550 fluorescent fixtures (based on 36W luminaires). This was achieved simply through manual switching off — not through motion sensors or timers.

There were subtler findings as well: changes in computer screen use, printer settings, shared equipment habits, and cleaning routines. These didn’t show up in the metering immediately. But they created a new culture of attention — one that made it easier for efficiency measures to embed and endure.

No investment was made in new devices. No changes were implemented in the BMS. The savings came from observing behavior, building trust, and creating social pathways for change to become visible.

These figures, while modest compared to deep retrofits, are instructive. They show that the first 10% to 20% of energy savings in a building may not require capital — only coordination.

For us, this is not a minor insight. It’s a strategic one. It suggests that before looking for smarter systems, we need to look more closely at what the existing ones are already capable of — if used differently.

V. Conclusion – Toward a Broader Definition of Engineering

We began this project with a technical mindset. Like many engineers, we believed energy performance was a matter of better systems, clearer logic, and tighter control. What we discovered — slowly, and sometimes uncomfortably — is that even the most sophisticated system will fall short if it does not align with the people using it.

This does not diminish the value of technical expertise. On the contrary, it demands more of it. It requires that engineering extend its scope: not only to simulate systems, but to observe context. Not only to optimize performance curves, but to understand patterns of behavior. Not only to define control strategies, but to ask how those strategies are interpreted, modified, or abandoned in daily practice.

What the PAPEO project gave us — and what we’ve now integrated into our work at BAARCH — is a fuller picture of what energy work really involves. It’s not just physics. It’s also psychology. It’s not just capital investment. It’s cultural investment. And it’s not just performance metrics. It’s relational dynamics — trust, fairness, visibility, and dialogue.

We’ve come to believe that the first layer of any energy intervention should not be hardware, but conversation.

This may sound simple. But in our experience, it’s rare.

Most energy strategies start with devices — sensors, meters, controls. Ours now starts with listening. Because that is where the real operational constraints emerge. That’s where silent resistance becomes visible. That’s where unknown allies — informal leaders, frontline staff, overlooked contributors — can be identified and mobilized.

These are not soft factors. They’re structural ones. They determine whether an intervention becomes embedded or ignored. Whether it shifts culture or reinforces fatigue. Whether the building evolves — or stays stuck.

Human-centered engineering isn’t a rebranding. It’s a rebalancing.

If we want our buildings to perform, we have to stop thinking of people as the problem. They are the key to the solution. And it’s time we start designing with them in mind.

If this resonates with your experience in buildings, we invite you to start the conversation.